Microtubule-associated protein (MAP)-rich tubulin is purified from porcine brain using a modified Shelanski et al. method. The resulting protein contains approximately 70% tubulin and 30% MAPs. Supplied as a lyophilized powder. Shipped at ambient temperature, powder stored at 4°C. The MAPs in this product act to stabilize microtubules and to enhance tubulin polymerization. MAP rich tubulin can polymerize efficiently at 1-2 mg/ml in the absence of glycerol.

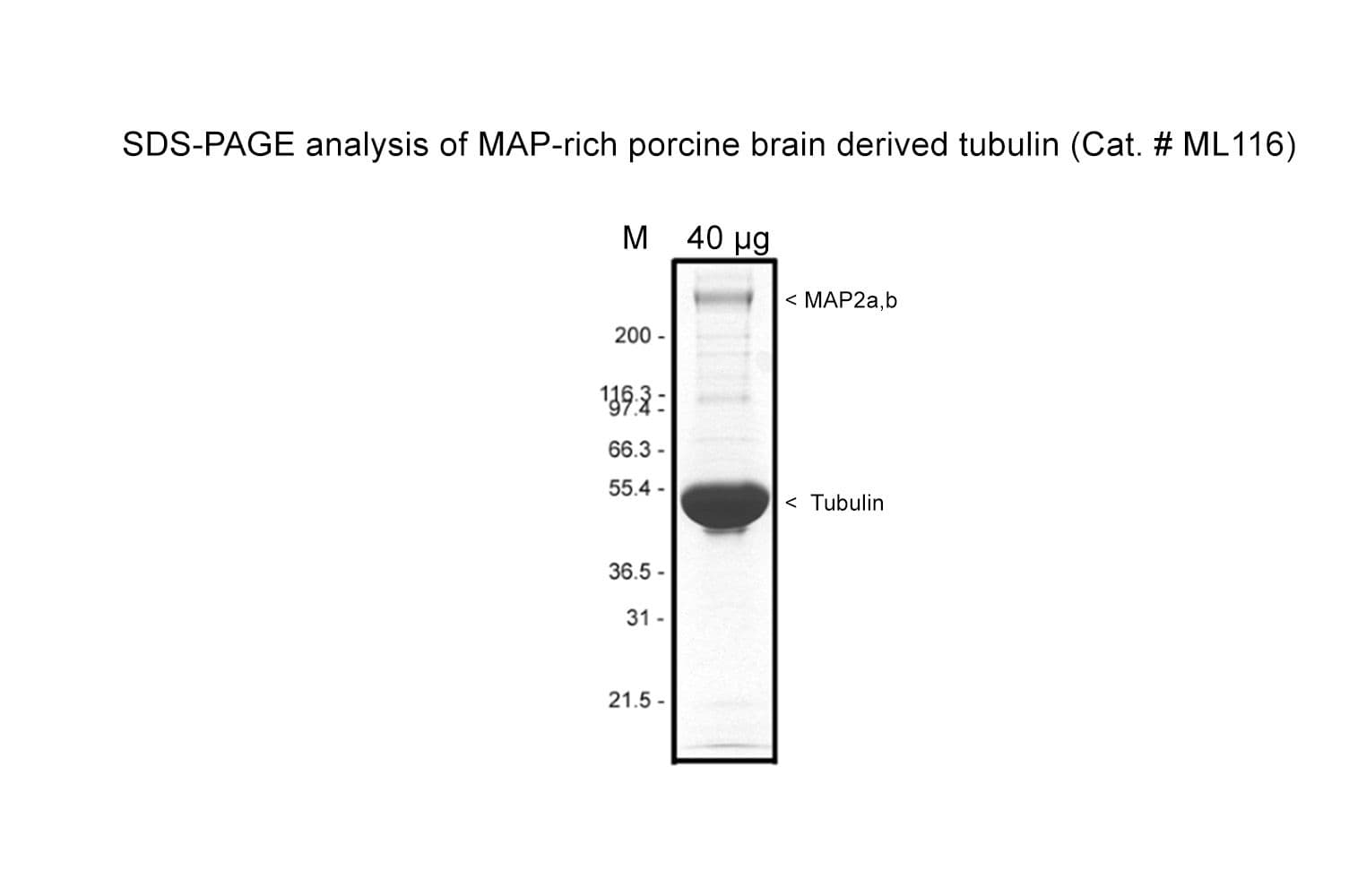

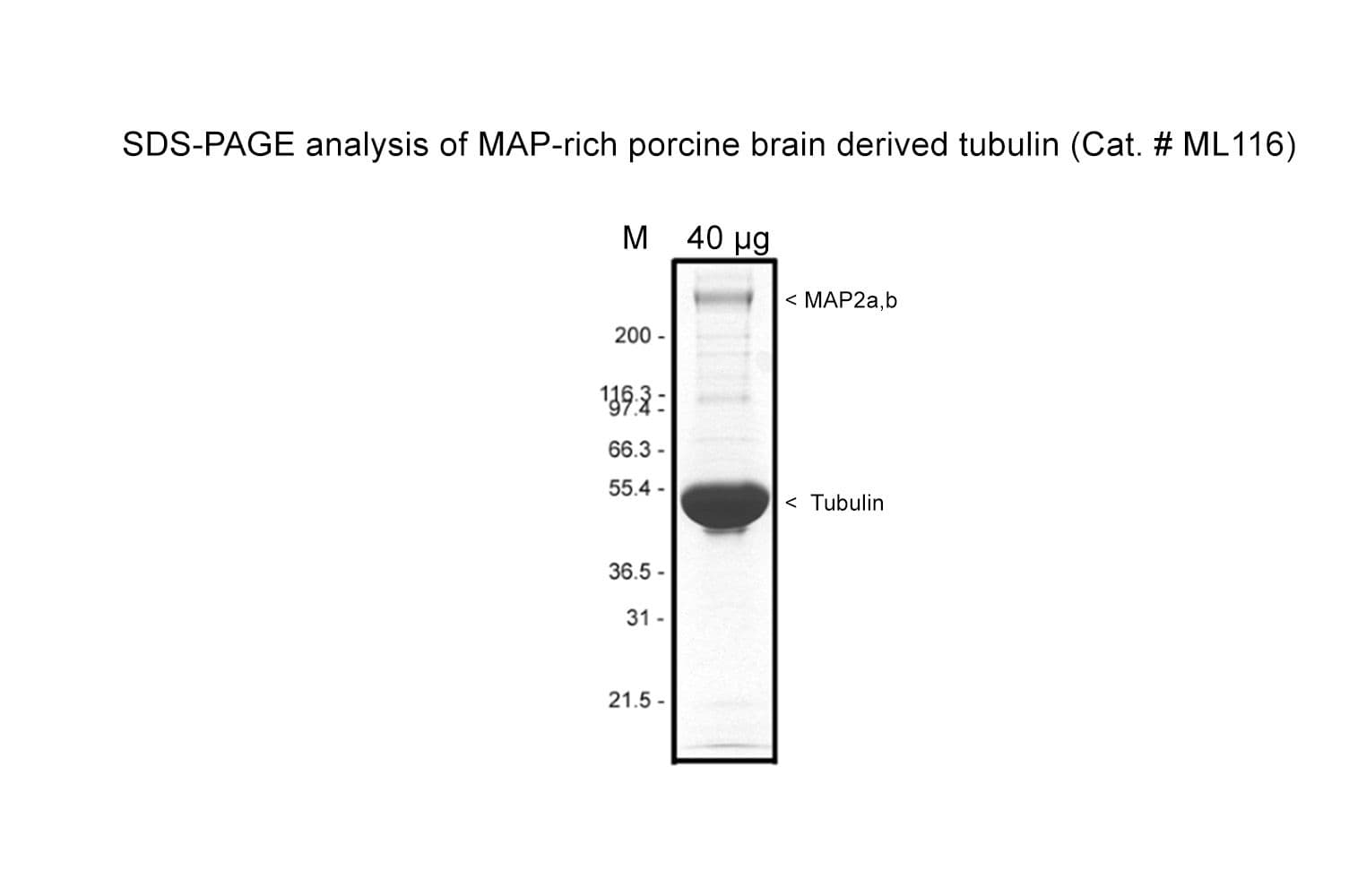

Tubulin is a heterodimer of α- and β-isotypes, each 55 kDa. SDS-PAGE shows a single 55 kDa band. The molecular weight of the functional heterodimer is 110 kDa. MAPs vary in molecular weight and include MAP1/2 (~250 kDa) and Tau isoforms (~37-44 kDa)

Protein purity is assessed by scanning densitometry of Coomassie Blue stained protein on a 4-20% polyacrylamide gel. Purity is determined to be ~70% tubulin and ~30% microtubule associated protein (MAP).

The biological activity of ML116 is evaluated using a tubulin polymerization assay, which monitors microtubule formation by measuring absorbance at 340 nm. Under the test conditions (2 mg/ml tubulin in General Tubulin Buffer plus 1 mM GTP, 180 µl volume, 37 °C, 0.8 cm pathlength), the OD340nm should reach between 0.3 and 0.5 within 30 minutes.

Cat. #ML116